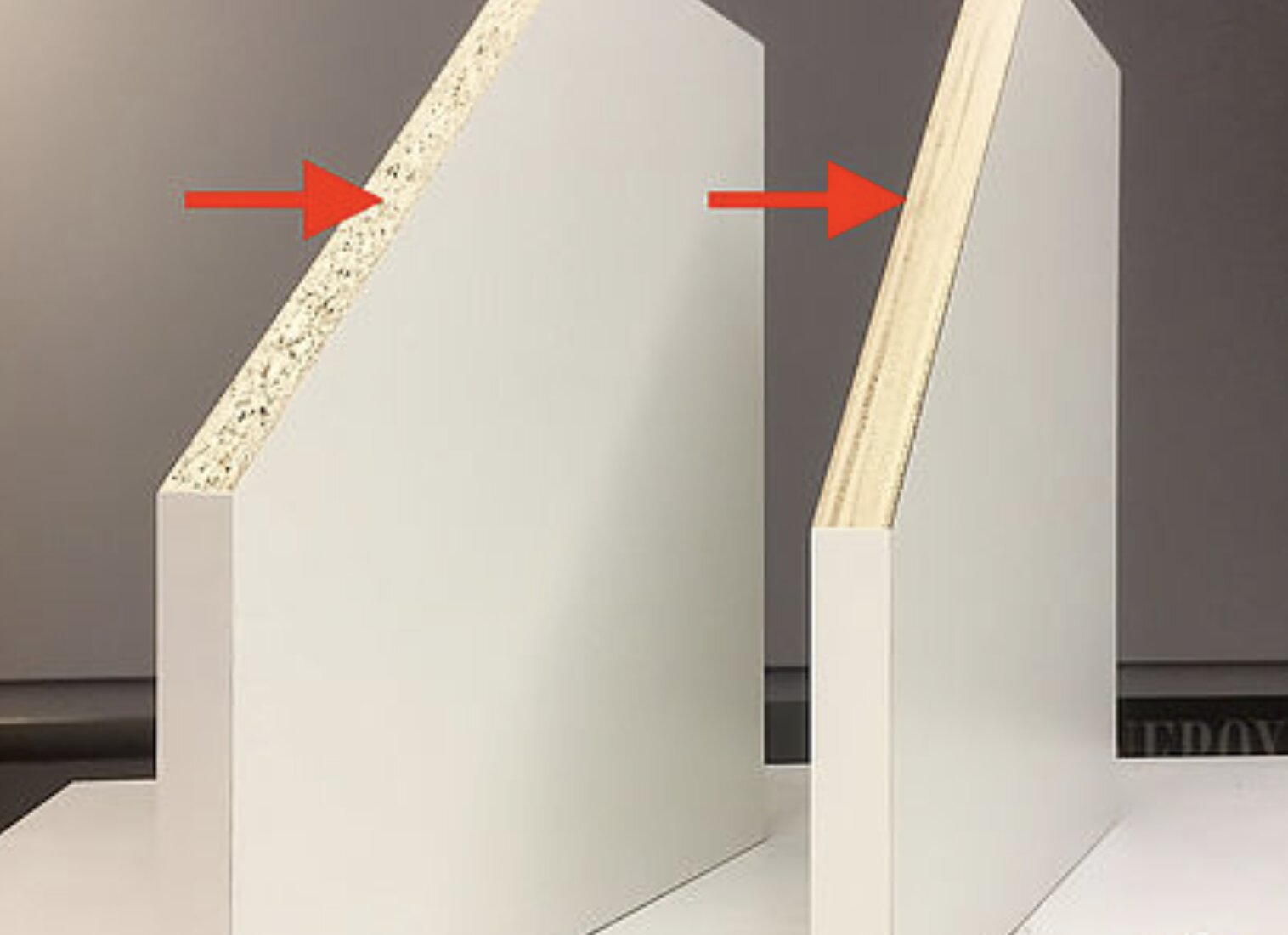

Substance is worth as much as appearance, if not more. In our contemporary furnishings and in all our standard kitchens, the hidden structures, when no customizations are needed, are always made with laminated plywood (or blockboard) panels and not with melamine chipboard panels. Why is this? Simply because the first material has multiple advantages over the second and follows our philosophy of uncompromising quality and respect for the environment. Let's look in detail at the differences between the two materials. Panel melamine or faced chipboard. Faced chipboard is a wood chipboard panel covered on one side, or on both sides, with melamine paper, which is a synthetic material made up of very thin sheets of paper (about a tenth of a mm) impregnated with melamine resin. The use of this paper means that faced chipboard is often also called melamine panel. It is considered a rather economical product; however, the development of increasingly realistic papers, combined with remarkable hardness and resistance to scratches and solvents on the surface, makes this product widely used in the world of furniture. Faced chipboard, being in fact an agglomerate of wood processing waste, paper, and urea and melamine glues, is a source of formaldehyde emissions into the environment (carcinogenic if inhaled) and its use should therefore be avoided in domestic environments. To obtain a furniture panel with zero formaldehyde emissions, blockboard should be used, covered with laminate and using formaldehyde-free glues (such as polyurethane), but many furniture manufacturers prefer to continue using melamine chipboard, due to its much lower cost compared to laminated blockboard, which allows them to compete on product price or otherwise achieve a higher profit. Panel laminated plywood or blockboard. Plywood is a product made with sheets that can be obtained from birch, poplar, and beech. These types of wood have a soft consistency, so they are certainly easy to work with. For the correct creation of the veneer, the plywood panel, an odd number of sheets should be overlapped, so that the grain of the first and last layer have the same direction. Blockboard panels are made up of a series of slats placed side by side and glued together, enclosed between two thin MDF panels on which HPL laminate sheets are applied (High Pressure Laminate (HPL) is usually produced with flat presses in sheets with thicknesses ranging from 0.5 to 20 mm. It is very resistant and is also used for exterior facades, bathrooms, kitchen tops, and workbenches, and wherever a truly robust surface is needed). These panels were created alongside plywood, to have boards as solid as solid wood, but without its defects; in fact, blockboard, which is generally made of poplar strips (the ones we use are fir), maintains excellent resistance to bending, in the longitudinal direction, easily holds screws inserted into it, and does not deform like solid wood. This allows this material to be used for the construction of higher quality furniture than those made with chipboard or MDF, while still maintaining excellent stability. All panels are then edged with PVC edging which, in addition to providing greater resistance, completely insulates against any penetration of moisture inside the panel itself. As you can imagine, the advantages of laminated wood panels are many: - No formaldehyde release - Greater resistance - Lower specific weight (i.e. lower consumption for transport and storage) - High capacity to hold standard and self-tapping screws - Extremely wear-resistant and hygienic laminate - Reusable and recyclable For us, design also means quality where it cannot be seen, because time is not an enemy but an ally of quality.

PHONE

SOCIAL

ADDRESS

+39 0324 262212

via Bagni 21

Crodo VB

28862

Italy

© Michele Anderlini Design 2025 - PI 00417458882

A soul...of quality!

A soul...of quality!

2023-03-08 10:34

2023-03-08 10:34

Array() no author 88675

MATERIALS AND FINISHES, laminato, bilaminato, finiture-arredi, struttura-mobili, materiali-arredamento, truciolare, multistrato, multistrati,

High-performance internal structures for quality furnishings.

PHONE

SOCIAL

ADDRESS

+39 0324 262212

via Bagni 21

Crodo VB

28862

Italy

© Michele Anderlini Design 2025 - PI 00417458882